The old take-make-use-lose model of industrial design has depleted resources and dumped waste into the environment. By taking nature as our model and mentor, we can transform manufacturing — and the earth, says economist Kate Raworth.

Traveling through Europe a few years ago, I met Prakash, a student from India who was studying for an advanced engineering degree in Germany. When I asked whether he had opted to learn about ecologically smart technologies, he replied, “No, India has other priorities — we are not rich enough to worry about that yet.” Surprised, I pointed out that almost half of India’s land is degraded, the nation’s groundwater levels are falling fast, and air pollution is the worst in the world. A flicker of recognition crossed his face, but he just smiled and repeated his words, “We still have other priorities.”

In one quick conversation, Prakash summed up the economic story that has been circulating for decades: poor countries are too poor to be green. What’s more, they don’t need to be, because economic growth will eventually clean up the very pollution that it creates, and replace the resources that it runs down.

It’s a story that once appeared to be backed up by data. But, despite its continuing grip on the imagination of politicians and publics alike, it has turned out to be a myth, in India just as in the rest of the world. “India has performed remarkably economically,” points out Muthukumara Mani, a World Bank senior environmental economist, “but that’s not reflected in its environmental outcomes. ‘Grow now, clean up later’ really doesn’t work.”

Rather than wait for growth to clean up the environment — because it won’t — it is far smarter to create economies that can restore and renew the cycles of life.

Ecological degradation is not a luxury concern for countries to leave on one side until they are rich enough to give it their attention. Rather than wait for growth to clean it up — because it won’t — it is far smarter to create economies that are regenerative by design, restoring and renewing the local-to-global cycles of life on which human well-being depends.

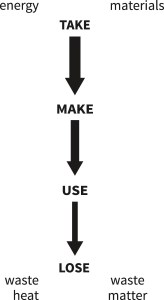

The last 200 years of industrial activity have been based upon a linear industrial system whose design is inherently degenerative. The essence of that industrial system is the cradle-to-grave manufacturing supply chain of take, make, use, lose: extract earth’s minerals, metals, biomass and fossil fuels; manufacture them into products; sell those on to consumers who — probably sooner rather than later — will throw them “away.”

When drawn in its simplest form (above), it looks something like an industrial caterpillar, ingesting food at one end, chewing it through and excreting the waste out of the other end. This ubiquitous industrial model has delivered strong profits to many businesses and has financially enriched many nations in the process. But its design is fundamentally flawed because it runs counter to the living world, which thrives by continually recycling life’s building blocks such as carbon, oxygen, water, nitrogen and phosphorus.

Industrial activity has broken these natural cycles apart, depleting nature’s resources and dumping too much waste in her sinks. By extracting oil, coal and gas from under land and sea, burning them, and dumping carbon dioxide in the atmosphere. Turning nitrogen and phosphorus into fertiliser, then offloading the effluent—from agricultural runoff and sewage—into lakes and oceans. Uprooting forests to mine metals and minerals that, once packed into consumer gadgets, are then cast onto e-waste dumpsites, with toxic chemicals leaching out into the soil, water and air.

Regenerative design embraces biosphere stewardship and recognizes that we have a responsibility to leave the living world in a better state than we found it. It calls for creating enterprises whose core business helps to reconnect nature’s cycles, and that gift as much as they can.

Says biomimicry expert Janine Benyus, “We are still acting like toddlers expecting Mother Nature to clean up after us.”

For Janine Benyus (TED Talk: Biomimicry in action), a leading thinker and doer in the field of biomimicry, this notion of generosity has become the design mission of a lifetime. As she told me, “We are big-brained animals, but we are newcomers on this planet, so we are still acting like toddlers expecting Mother Nature to clean up after us. I want us to take on this design task and become full participants in every one of nature’s cycles. Start with the carbon cycle — let’s learn to halt our industrial ‘exhale’ of carbon pollution and then, by mimicking plants, learn to ‘inhale’ carbon dioxide into our products and store it for centuries in rich agricultural soils. Once we’ve cut our teeth on the carbon cycle, let’s apply what we have learned to the phosphorus, nitrogen and water cycles, too.”

To discover the essence of generous design, Benyus suggests that we take nature as our model, measure and mentor. With nature as model, we can study and mimic life’s cyclical processes of take and give, death and renewal, in which one creature’s waste becomes another’s food.

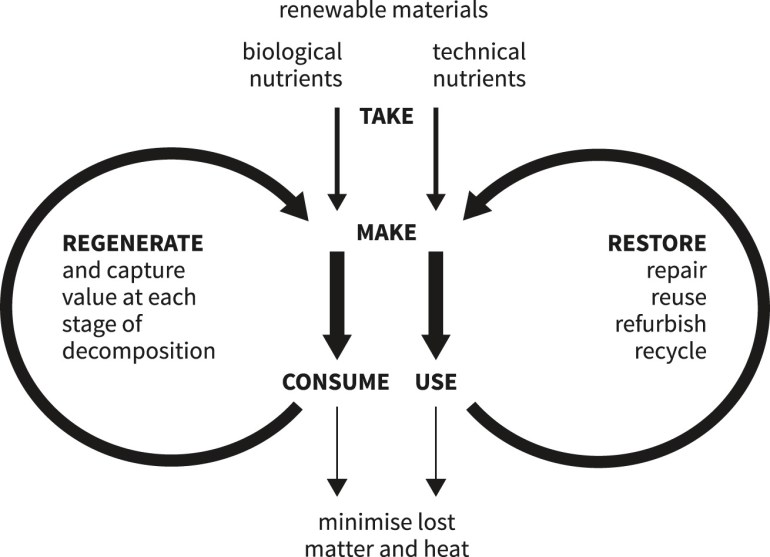

Industrial manufacturing has begun the metamorphosis from degenerative to regenerative design through what has come to be known as the “circular economy.” It harnesses the endless inflow of the sun’s energy to continually transform materials into useful products and services. So bid farewell to the linear industrial economy’s caterpillar as, before your eyes, it turns into a butterfly (see the above diagram from the Ellen MacArthur Foundation).

What are the design features that enable this industrial butterfly to take flight? First, focus on the old cradle-to-grave mentality of the linear economy that incited the 20th century’s voracious mining for minerals, drilling for oil and burning of waste. Cradle-to-cradle thinking is what characterizes the circular economy. It runs on renewable energy — from solar, wind, wave, biomass and geothermal sources — eliminating all toxic chemicals and, crucially, eradicating waste by design. It does so by recognizing that “waste equals food”: instead of heading for landfill, the leftovers from one production process — be they food scraps or scrap metal—become the source materials for the next.

The key to making this work is to think of all materials as belonging to one of two nutrient cycles: either biological nutrients such as soil, plants and animals, or technical nutrients such as plastics, synthetics and metals. Materials are never “used up” and thrown away but are used again and again and again through cycles of reuse and renewal. The secret to using biological nutrients endlessly is to: ensure that they are harvested no faster than nature regenerates them, harness their many sources of value as they cascade through the cycles of life, and design production in ways that give back to nature.

Mobile phones are chock-full of gold, silver, cobalt and rare earth metals, but as of 2010 in the EU, 85 percent ended up in landfills or lay defunct in some drawer.

Take coffee beans as a simple example: less than 1 percent of every bean ends up in a cup of coffee, and the leftover coffee grounds are rich in cellulose, lignin, nitrogen and sugars. It would be foolish to throw such organic treasure straight on to a compost heap or, far worse, into a trash bin, but this happens in homes, offices and coffee shops worldwide. Coffee grounds, it turns out, make an ideal medium for growing mushrooms, and then can be used as feed for cattle, chickens and pigs, and so are returned to the soil as manure. From the humble coffee bean, imagine scaling that principle up to all food, crops and timber, and scaling it out to every home, farm, firm and institution: it would start to transform our last-century forestry and food industries into regenerative ones that reap value from and then regenerate the living systems on which they depend.

In contrast, products made using technical nutrients, such as metals and synthetic fibers, do not naturally decompose, so they must be designed to be restored. How? Through repair, reuse, refurbishment, and — as a last resort — recycling. Mobile phones, for example, are chock-full of gold, silver, cobalt and rare earth metals, but are typically used for just two years. In the European Union, over 160 million mobile phones are sold annually, but in 2010, only 6 percent of used phones were being reused, and 9 percent disassembled for recycling; the remaining 85 percent ended up in landfills or lay defunct in the back of some drawer. In a circular economy, they would be designed for easy collection and disassembly, leading to their refurbishment and resale, or the reuse of all their parts. Scale those principles across all industries, and you start to turn 20th-century industrial waste into 21st-century manufacturing materials.

Still, the notion of a truly circular economy belongs with the fantasy of perpetual motion machines: a more accurate name would be the cyclical economy. No industrial loop can recapture and reuse 100 percent of its materials. Japan impressively recycles 98 percent of metal used domestically, but there’s still an elusive 2 percent leaking from that loop. And given enough time, all technical materials — from metals to plastics — will start to rust or decay.

We have the extraordinary luck of being bathed in a constant river of solar energy, so we can — like all living things—be ingenious in harnessing it to restore what we have created.

But if we start to look upon every object, be it an 18th-century building or the latest smartphone, as if it were a battery storing valuable materials and energy, then we begin to focus on retaining or reinventing that stored value. And since we have the extraordinary luck of being bathed in a constant river of solar energy, we can — like all living things — be ingenious in harnessing it to restore what we have created, and to regenerate the living world in which we thrive. In a degenerative industrial economy, value is monetary, and it is created by searching for ever-lower costs and ever-greater product sales. The typical result has been intense material throughflow. In a regenerative economy, that material throughflow is transformed into round-flow.

But the real transformation comes from a new understanding of value. “There is no wealth but life,” as art critic and social thinker John Ruskin wrote in 1860. His words were poetic, but they were prophetic too. Economic value lies not in the throughflow of products and services but in the wealth that is their recurring source. That includes the wealth embodied in human-made assets (from tractors to houses) but also the wealth embodied in people (from their individual skills to community trust), in a thriving biosphere (from the forest floor to the ocean floor) and in knowledge (from Wikipedia to the human genome). Yet even these forms of wealth eventually dissipate: tractors rust, trees decompose, people die, ideas are forgotten. Only one form of wealth persists through time and that is the regenerative power of life, powered by the sun.

Excerpted with permission from the new book Doughnut Economics: 7 Ways to Think Like A 21st-Century Economist by Kate Raworth. Published by Chelsea Green Publishing. Copyright © 2018 by Kate Raworth.

Watch her TED Talk here: